1 Introduction

1.1 Purpose

of The Manual

1.2 Project Description

1.3 Objectives of the EM&A Programme

1.4 Scope of The EM&A Programme

1.5 Organisation and Structure of the EM&A Programme

1.6 Structure of the EM&A Manual

2 EM&A General Requirements

2.1 Introduction

2.2 EM&A

3 aIR qUALITY

3.1 Introduction

3.2 Dust

3.3 Ambient

VOCs, Ammonia and H2S

3.4 Emissions of the Thermal Oxidiser

3.5 Emissions

of Landfill Gas Flare

3.6 Emissions of LFG Generator

3.7 ODOUR

3.8 Event

and Action Plan

3.9 Meteorological

Data

4 Water quality

4.1 Introduction

4.2 Surface Water

4.3 Groundwater

4.4 Leachate

4.5 Event

and Action Plan for Water Quality Monitoring

5 Landfill Gas

5.1 Introduction

5.2 Methodology and Criteria

5.3 Monitoring Parameters, Locations and Frequency

5.4 Monitoring Equipment

5.5 Laboratory Measurement / Analysis

5.6 Compliance Requirements

6 Noise

6.1 Introduction

6.2 Methodology

and Criteria

6.3 Monitoring

Equipment

6.4 Monitoring

Locations

6.5 Baseline

Monitoring

6.6 Impact

Monitoring

6.7 Event

and Action Plan

7 Waste Management

7.1 General

7.2 Mitigation

Measures

7.3 Site Audit/Inspection

8 Ecology

8.1 Introduction

8.2 Mitigation Measures

8.3 Compensation

8.4 Environmental

Monitoring and Audit

9 Landscape and Visual

9.1 Introduction

9.2 Mitigation Measures

9.3 Design

Phase Audit

9.4 Construction

Phase Audit

9.5 Operation/Restoration

Phase Audit

9.6 Aftercare

Phase Audit

10 Site environmental Audit

10.1 Site Inspection

10.2 Environmental

Management Plan

10.3 Compliance with Legal and Contractual Requirements

10.4 Environmental

Complaints

10.5 Log-Book

11 Reporting

11.1 General

11.2 Baseline

Monitoring Report

11.3 Monthly

EM&A Reports

11.4 Quarterly

EM&A Summary Reports

11.5 Annual

EM&A Review Report

11.6 Final

EM&A Summary Report

11.7 Data

Keeping

ANNEXES

Annex A Implementation Schedule

Annex B Complaint and Monitoring Proforma

1

Introduction

1.1.1 Background

The Environmental Impact Assessment (EIA) Report and the associated Environmental Monitoring and Audit

(EM&A) Manual for the construction, operation, restoration and aftercare

of the South East New Territories Landfill Extension (SENTX) (hereafter

referred to as ��the Project��) have been approved under the Environmental Impact Assessment Ordinance (EIAO) in May 2008

(Register No.: AEIAR-117/2008). Since then, the Hong Kong SAR Government

has decided to reduce the scale of the design scheme of SENTX assessed in the

approved EIA Report and SENTX will

only receive construction waste. In

line with the changes proposed by EPD, the landfill contractor for SENTX, Green

Valley Landfill Limited (GVL), has developed a final scheme for SENTX

(hereafter ��the latest scheme��) in 2016.

This latest design complies with the requirements in the Technical Memorandum of the

Environmental Impact Assessment Process (EIAO-TM) and the current

Environmental Permit (EP-308/2008/B).

This updated EM&A Manual has taken into

account the findings and recommendation of the approved EIA Report and with updates taken from the current EP and the

latest design to reflect the necessary environmental monitoring and audit

(EM&A) requirements associated with the construction, operation/

restoration and aftercare of the SENTX under the latest design.

This updated Manual has been prepared with

reference to the approved EM&A Manual

prepared in May 2008, the current EP, the latest design and the EIAO-TM.

The purpose of the Manual is to provide information, guidance and

instruction to personnel charged with environmental duties and those

responsible for undertaking EM&A work during construction, operation/restoration

and aftercare phases of the SENTX.

It provides systematic procedures for the environmental monitoring and

auditing of the potential environmental impacts that may arise from the

Project.

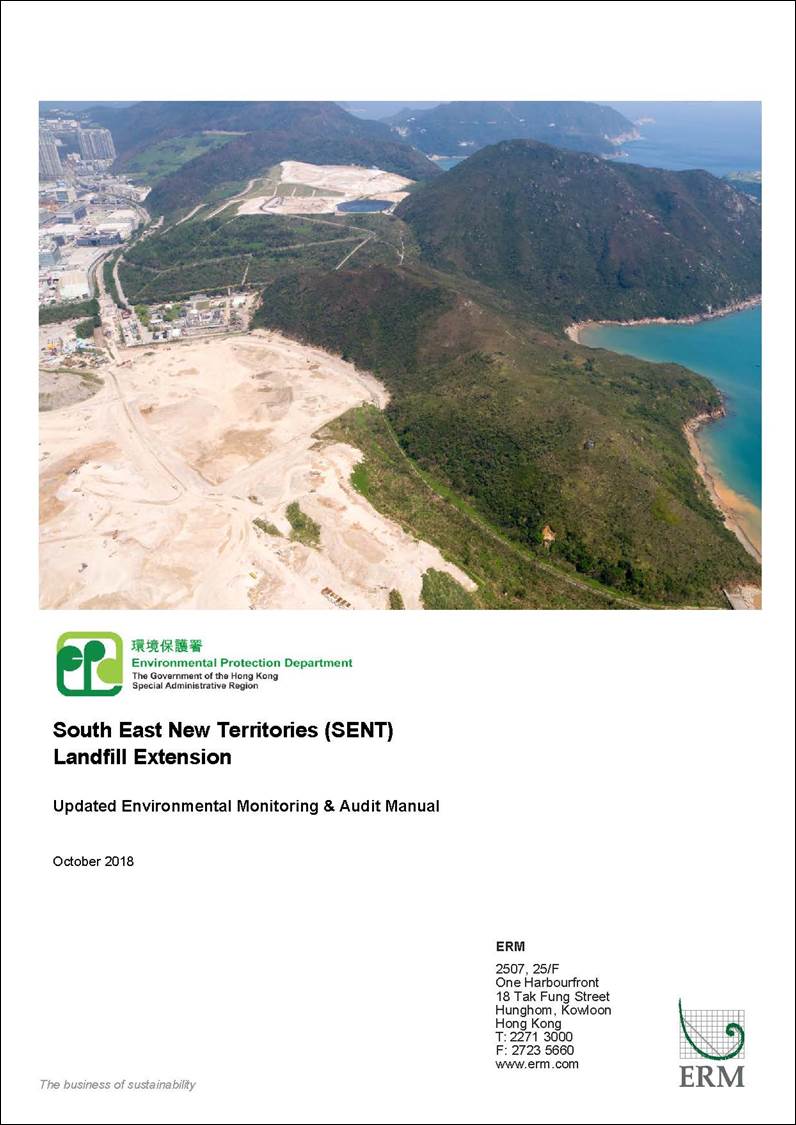

1.2.1 Background

The existing waste disposal facility in the South-east New

Territories is the SENT Landfill at Tseung Kwan O (TKO). The Hong Kong SAR Government has

identified a 13 ha site at TKO Area 137 for the extension of the SENT Landfill

(hereafter refer to ��SENTX��) (see Figure 1.2a).

Under the latest design, the SENTX has a net void capacity

of about 6.5 Mm3 and provides an additional lifespan of about 6

years, commencing operation upon exhaustion of the SENT Landfill. The SENTX will

receive construction waste only.

The design, construction, operation,

restoration and aftercare of the SENTX shall comply with the requirement

stipulated in the EP (EP-308/2008/B).

1.2.2 The Project

The SENTX is a piggyback landfill,

occupying the southern part of the existing SENT Landfill (including its

infrastructure area) and 13 ha of TKO Area 137. A layout plan of the SENTX is shown in Figure 1.2a.

The key elements of the construction, operation/restoration and

aftercare of the SENTX are described below.

Construction

of SENTX

Construction works will commerce about two

years prior to the operation of the SENTX.

The major construction works includes:

�P

Site

formation at the TKO Area 137 and the existing infrastructure area at SENT

Landfill;

�P

Construction

of surface and groundwater drainage systems;

�P

Construction

of the leachate containment and collection systems;

�P

Construction

of new leachate and landfill gas treatment facilities, site offices, maintenance

yards at the new infrastructure area;

�P

Construction

of new pipelines to transfer the leachate and landfill gas collected from the

existing SENT Landfill to the treatment facilities at the new infrastructure

area;

�P

Construction

of the site access and new waste reception facilities; and

�P

Demolition

of the facilities at the existing SENT Landfill infrastructure area.

Operation and Restoration of

SENTX

The

leachate and landfill treatment facilities will be commissioned and the first

phase of the SENTX will start operation upon

exhaustion of the SENT Landfill. Construction of the leachate containment

and collection system for the subsequent phases will continue while the first

phase of the SENTX is in operation.

The areas that reach the finished profile will be

progressively restored and landscaped.

Aftercare of SENTX

Upon the completion of final

filling and restoration, the aftercare of the SENTX will begin and last for 30

years. Regular site maintenance, collection and

treatment of landfill gas and leachate will be undertaken during the aftercare

period to ensure that the landfill complies with the required environmental

performance requirements and is safe.

The restored landfill may then be developed for various

passive

beneficial uses (eg open spaces, walking trails, etc).

An EM&A programme will be implemented throughout the

construction, operation/restoration and aftercare phases of the SENTX.

Implementation Programme

The key implementation of milestone of the Project is

indicatively

summarised in Table 1.2a.

Table 1.2a Estimated

Key Dates of

Implementation Programme

|

Key Stage of the

Project

|

Indicative Date

|

|

Start

construction

|

31

December 2018

|

|

Commissioning

of new infrastructure facilities

|

2020

|

|

Demolition

of existing infrastructure facilities

|

2021

|

|

|

|

|

Start

waste intake at SENTX

|

2021

or upon exhaustion

of SENT Landfill

|

|

Stop

taking waste at SENTX

|

2027

|

|

End

of aftercare for SENTX

|

2057

|

1.3

Objectives of the EM&A Programme

The potential environmental impacts associated

with the Project have been assessed and described in the approved EIA Report. Mitigation measures are required to

comply with the environmental criteria.

The updated mitigation measures associated with the latest design and

their implementation requirements are presented in the Implementation Schedule

(see Annex A[CL1]

). An EM&A

programme will be implemented to assess the effectiveness of measures and to

confirm that there will be no adverse environmental impacts during all phases

of the Project. Regular site audits

will be undertaken during the construction and operation/restoration phases to

check whether good site practices are properly implemented to prevent adverse

environmental impacts. Any

activities that have a potential to cause adverse environmental impacts are

identified before the adverse impacts occurred. Ad

hoc visits

to the impacted sites should also be undertaken in response to any complaints

or reported non-compliance with environmental standards in order to enable

prompt actions are taken to address the impacts.

This updated EM&A Manual provides details of the updated EM&A requirements

associated with the latest design (SENTX only accept construction waste). The main objectives of the EM&A

programme are to:

�P

verify the environmental impacts predicted in the EIA Report taking account of latest

design;

�P

monitor the performance of the Project and the effectiveness of

mitigation measures;

�P

determine Project compliance with regulatory requirements and

standards;

�P

provide an early indication should any of the environmental

control measures or practices fail to achieve the required standards;

�P

take remedial action if unexpected problems or unacceptable

impacts arise;

�P

provide a database against which any short or long term

environmental impacts of the Project can be determined; and

�P

provide data against which environmental audits may be undertaken.

Table

1.4a summarises the requirements at various

phases of the Project.

Table 1.4a Summary

of EM&A Requirements

|

Parameter

|

EM&A

Phase

|

|

Construction

|

Operation/

Restoration

|

Aftercare

|

|

Dust

|

P

|

P

|

P (b)

|

|

Ambient

Volatile Organic Compounds (VOC),

Ammonia and Hydrogen Sulphide (H2S)

|

P (a)

|

P

|

P

|

|

Stack

emissions from Flares and Thermal Oxidizers

|

|

P

|

P (d)

(flares only)

|

|

Odour

|

|

P

|

P (b)

|

|

Surface

Water

|

P

|

P

|

P

|

|

Groundwater

|

P (a)

|

P

|

P

|

|

Leachate

|

|

P

|

P

|

|

Landfill

Gas

|

P (a)

|

P

|

P

|

|

Noise

|

P

|

P

|

P (b)

|

|

Waste

Management (c)

|

P

|

P

|

|

|

Ecology

(c)

|

P

|

P

|

P

|

|

Landscape

and Visual (c)

|

P

|

P

|

P

|

|

Notes:

(a)

The monitoring

of VOCs, ammonia, H2S, groundwater and landfill gas during

construction would act as baseline monitoring for operation impact

(b)

The monitoring and

audit of dust, odour and noise in aftercare phase will only be required when

there are major maintenance / maintenance works requiring excavation of

waste.

(c)

EM&A scope

include audit works only.

(d)

Since the

leachate quantity will be significantly decreased during aftercare phase,

therefore, SBR/MBR tanks should be sufficient to treat the leachate to meet

the required standards without the need to operate the thermal oxidiser. Hence, stack emission monitoring will

only be conducted at flares only if the thermal oxidiser is no longer in use.

|

The scope of the EM&A programme is to:

�P

implement regular monitoring and site audit requirements and

undertake additional or ad hoc

monitoring if non-compliance identified;

�P

evaluate and interpret all environmental monitoring data on a

regular basis to provide an early indication should any of the environmental

control measures or practices fail to achieve the required performance

standards, and to verify the environmental impacts predicted in the EIA Report taking account of the latest

design;

�P

liaise with, and provide environmental advice (as requested or

when otherwise necessary) to construction/operation site staff on the

comprehension and consequences of the environmental audit;

�P

identify and resolve environmental issues that may arise from the

Project;

�P

investigate environmental complaints associated with the Project;

�P

check and evaluate the Contractor's overall environmental

performance, and the effectiveness of the remedial actions; and

�P

prepare and submit EM&A reports which summarise project

monitoring and auditing data, with full interpretation illustrating the

acceptability or otherwise of any environmental impacts and identification or

assessment of the implementation status of agreed mitigation measures.

1.5

Organisation and Structure of the

EM&A Programme

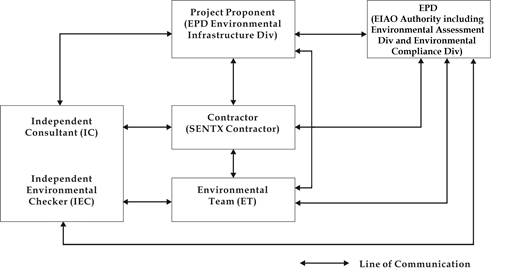

1.5.1 Project Organisation

The proposed organisation of

the personnel involved in the EM&A process is illustrated in Figure 1.5a.

Figure 1.5a Organisation Chart

The roles and responsibilities of

the various parties are summarised below:

�P

Project Proponent: Environmental Infrastructure Division, EPD

�P

Independent Consultants (IC): The IC should be responsible for

overseeing the Project undertaken by the Contractor and for ensuring that the

Project is undertaken by the Contractor in accordance with the specification

and contractual requirements. The

responsibilities for the IC include the

following:

-

Verify

and check the Contractor��s activities and ensure that the requirements in the

Contract Specifications, including the implementation and operation of the

environmental mitigation measures and other aspects of the EM&A programme

are fully complied with ().

�P

Contractor: The landfill contractor should be

responsible for carrying out design, construction, operation, restoration and aftercare

of the SENTX.

The Contractor

should:

-

implement environmental controls and mitigation as set out in this EM&A Manual as well as any additional measures necessary for compliance

with the environmental control standards;

-

assist the Project Proponent to establish an ET to undertake the

monitoring and reporting of the EM&A requirements outlined in this EM&A Manual;

-

submit proposals on mitigation measures in case of exceedances of

Action and Limit levels in accordance with the Event and Action Plans;

-

implement

measures to reduce impact where Action and Limit levels are exceeded;

-

implement the corrective actions instructed by Project Proponent and advised by the ET;

-

participate in the site inspections undertaken by the ET and undertake

any corrective actions advised by the ET; and

-

adhere to the procedures for carrying out complaint

investigation.

�P

Environmental

Team (ET): The ET

should be responsible for

ensuring the implementation of the mitigation measures and EM&A requirements

recommended in this EM&A

Manual, and report to the Project Proponent and the EPD (EIAO Authority) on all

environmental aspects of the Project. The ET should be led and

managed by the ET Leader (or sometimes called Environmental Manager). The ET Leader should have relevant education,

training, knowledge, experience and professional qualifications. The ET Leader should possess at least 7 years of experience in

EM&A and/or environmental management.

The ET shall not be in any way an associated body of the Contractor or

the IEC for the Project. The ET should:

-

Monitor of the various environmental parameters as required by this or subsequent revisions to the Manual;

-

assess the EM&A data and review the success of the EM&A

programme determining the adequacy of the mitigation measures implemented and

the validity of the predictions in the approved EIA Report taking account of the latest design;

-

conduct site inspections to investigate and inspect the work

equipment and methodologies with respect to pollution control and environmental

mitigation, monitor compliance with environmental protection specifications,

and to anticipate environmental issues that may require mitigation before the

problem arises;

-

compile the environmental monitoring data and report the status of

the general site environmental conditions and the implementation of mitigation

measures resulting from site inspections;

-

review working programme and methodology, and comment as

necessary;

-

investigate and evaluate complaints, and identify corrective measures;

-

advice on environmental improvement, awareness, enhancement

matters, etc, on site;

-

report on the environmental monitoring and audit results and the

wider environmental issues and conditions to the Project Proponent and the EPD (EIAO Authority);

-

adhere to the agreed protocols in the event of exceedances or

complaints; and

-

the ET Leader will keep a contemporaneous log-book and record

each and every instance or circumstance or change of circumstances which may

affect the findings of approved EIA Report (taking account of the latest

design) and non-compliance with the EP.

�P

Independent

Environmental Checker (IEC): An IEC

will be appointed, as part of the IC, who should verify the overall

environmental performance of the Project.

The IEC should be responsible for verifying all environmental

submissions required under the EM&A programme and EP to the EPD (EIAO

Authority). The IEC should possess at

least 7 years of experience in EM&A and/or environmental management. The IEC shall not be in any way an associated body of the

Contractor or the ET for the Project.

The IEC should:

-

audit the EM&A works performed by the ET (at least at

monthly intervals);

-

carry out random sample check and audit the monitoring

activities and results (at least at monthly intervals);

-

conduct site inspections and report the audit/site inspection

results and other environmental performance reviews to the Project Proponent;

-

review and verify the EM&A reports submitted by the ET;

-

review the effectiveness of environmental mitigation measures and

project environmental performance;

-

check the mitigation measures recommended in this updated

EM&A Manual, and ensure they are properly implemented in timely manner when

required;

-

review the proposal on mitigation measures submitted by the

Contractor in accordance with the EAP; and

-

adhere to the procedures for carrying out complaint

investigation.

�P

EPD: The Authority under the EIAO, including the EPD Environmental

Assessment Division and EPD Environmental Compliance Division. The EPD will be the authority to approve

all submissions under the EIAO.

1.6

Structure of the EM&A Manual

The remainder of

this updated EM&A Manual is set out as follows:

�P

Section 2 sets out the

EM&A general requirements;

�P

Section 3 details the

requirements for air quality monitoring;

�P

Section 4 details the

requirements for water quality and leachate monitoring;

�P

Section 5 details the

requirements for landfill gas monitoring;

�P

Section 6 details the

requirements for noise monitoring;

�P

Section 7 details the

requirements for waste management audit;

�P

Section 8 details the

requirements for ecological mitigation measures;

�P

Section 9 details the

requirements for landscape and visual impacts mitigation measures;

�P

Section 10 describes the

scope and frequency of site auditing;

�P

Section 11 details the

EM&A reporting requirements;

�P

Annex A contains the

implementation schedule summarising all applicable mitigation measures in the approved EIA Report taking account of the latest design; and

�P

Annex B contains the

monitoring and complaint log sheets.

This updated EM&A Manual is an evolving

document that should be updated to maintain its relevance as the Project

progresses. The primary focus for

these updates will be to ensure the impacts predicted and the recommended

mitigation measures remain consistent and appropriate to the manner in which

the works are to be carried out. Any changes to the programme shall be

justified by the ET Leader and verified by the IEC before submission to the

EIAO Authority for approval.

2

EM&A General Requirements

The general

requirements of the EM&A programme are described in this Section. The scope of the programme is developed

with reference to the findings and recommendations from the approved EIA Report taking account of the latest

design.

The potential

environmental impacts and the implementation of the recommended mitigation measures

for the construction, operation, restoration and aftercare of the SENTX should

be monitored through the EM&A programme specified in this EM&A

Manual.

The EM&A programme will include regular and

ad hoc site inspections/ audits and environmental monitoring. The programme also include the

mechanisms to review and assess the Contractor��s environmental performance,

ensuring that the recommended mitigation measures have been properly

implemented, and that timely resolution of received complaints are managed and

controlled in a manner consistent with the recommendations of the approved EIA Report.

2.2.1 Environmental Monitoring

Baseline monitoring and impact

monitoring during the construction, operation, restoration and aftercare of the

SENTX should be managed by the ET. The monitoring

should be focused on the following aspects:

�P

dust and odour impacts on air sensitive receivers;

�P

ambient VOCs, ammonia & H2S along the SENTX Site

boundary;

�P

stack emissions from the flares of landfill gas treatment

facilities and the thermal oxidisers of Leachate Treatment Plant (LTP);

�P

water quality impacts on groundwater and surface water;

�P

landfill gas concentration at the SENTX Site boundary; and

�P

effluent flow and quality from the LTP, and leachate level in the

landfill;

These are discussed further in Sections 3 to 10 of this EM&A Manual.

2.2.2 Compliance with Action and Limit Levels

The action and limit levels should

be defined for environmental monitoring at designated monitoring locations

exceeding which a prescribed response should be required. Individual action and limit levels

should be quantitatively defined for the respective environmental monitoring

parameters according to the following basic principles:

Action

Level

Action levels indicate

deteriorating ambient environmental quality potentially due to the Project

implementation. It acts as a sign

to trigger stepped up monitoring and appropriate remedial actions in order to

rectify any mal-practices or non-conformance of Project activities thereby

preventing the deterioration of environmental quality and to resume the ambient

environmental quality back to normal levels.

Limit

Level

Limit levels are the statutory

and/or contractual levels above

which environmental conditions are considered unacceptable. If limit levels were exceeded, the

relevant part of the works should not be continued without implementation of

immediate remedial action, including a critical review of plant and working

methods.

2.2.3 Event and Action Plans

The purpose of the Event and Action

Plans (EAPs) is to provide, in association with the EM&A activities,

procedures for ensuring that if any significant environmental incident (either

accidental or through inadequate implementation of mitigation measures) on the

part of the Contractor does occur, the cause should be quickly identified and

remediated, and the risk of a similar event recurring is reduced.

2.2.4 Site

Inspections/Audits

In addition to monitoring works as the means of assessing

the ongoing environmental performance of the Project, the ET and IEC should

undertake site inspections and audits of on-site practices and procedures. The primary objectives of the site

inspection and audit programme are to ensure the good site practices and

mitigation measures in this updated EM&A

Manual are properly

implemented and to assess the effectiveness of these measures.

The findings of site inspections and audits should be made

known to the Contractor and the IEC at the time of the inspection to enable the

rapid resolution of identified non-compliances. Non-compliances, and the corrective

actions undertaken, should be reported in the monthly EM&A reports.

Section 10 of this updated EM&A

Manual presents details of the scope and frequency of on-site inspections and

defines the range of issues that the audit protocols should be designed to

address.

2.2.5 Enquiries, Complaints and Requests for Information

Enquiries, complaints and

requests for information can be expected from a wide range of individuals and

organisations including members of the public, Government departments, the

press and television media and community groups.

All enquiries concerning the environmental

impacts of the Project, irrespective of how they are received, should be

reported to the Project Proponent and IEC and directed to the Contractor and ET

who should set up procedures for handling, investigation and storage of such

information. The following steps

should be followed:

(a)

The ET should notify the IEC of the nature of the enquiry.

(b)

An investigation should be initiated to determine the validity of

the complaint and to identify the source(s) of the problem.

(c)

The ET and the Contractor should undertake the following steps, as

necessary:

�P

investigate and identify source(s) of the problem;

�P

if considered necessary by the IEC, undertake additional

monitoring to verify the existence and severity of the alleged complaint;

�P

identify

necessary remedial measures and implement as soon as possible;

�P

repeat the monitoring to verify effectiveness of mitigation

measures; and

�P

repeat review procedures to identify further possible areas of

improvement if the repeat monitoring results continue to substantiate the

complaint.

(d)

The outcome of the investigation and the actions taken should be

documented on a complaint proforma (see Annex B) and should be verified by the IEC. A formal response to each complaint

received should be prepared by the Contractor within a maximum of five working

days and submitted to the IEC for review.

The ET should submit the formal response to the Project Proponent for

approval. The Project Proponent

will notify the concerned person(s) of the findings of the complaint

investigation and the actions taken, if required.

(e)

All enquiries/complaints that trigger this process should be

reported in the monthly EM&A reports, which should include results of

investigations undertaken by the ET and the Contractor, and details of the

measures taken, and additional monitoring results (if deemed necessary). It should be noted that the receipt of

complaint or enquiry should not be, in itself, a sufficient reason to introduce

additional mitigation measures.

In all cases the complainant will be notified

of the findings of the investigation.

2.2.6 Reporting

With respect to the identified potential impacts and the

nature and frequency of the EM&A to be undertaken, it is considered that

real-time reporting of the monitoring data through a dedicated website is not

applicable. However, the monitoring

data should be uploaded to the Project website at regular interval to be agreed

by the EPD (EIAO Authority), Contractor and the Project Proponent.

Monthly EM&A reports prepared by the ET

should be certified by the ET Leader and verified by the IEC prior to

submission to the Project Proponent and EPD (EIAO Authority). The monthly EM&A reports should be prepared and

submitted within 10 working days of the end of each reporting month. Additional details on reporting

protocols are presented in Section 10.

2.2.7 Cessation of EM&A

The ET will continue to manage the

environmental monitoring and site inspection/audit until completion of the

Project (i.e. until the completion of the aftercare period).

3

aIR qUALITY

The general requirements,

methodology, equipment, and mitigation measures for the monitoring and audit of

potential air quality impacts associated with different phases of the Project

are described in this Section.

The air quality monitoring parameters includes:

�P

Dust;

�P

Ambient volatile organic compounds (VOCs), ammonia and

hydrogen sulphide (H2S);

�P

Odour;

�P

Emission from the thermal oxidiser of the LTP;

�P

Emission from LFG flares; and

�P

Emission from LFG generator.

The requirements of setting up a

meteorological station are also described in this Section.

The mitigation measures recommended

to control air quality impacts are summarised in Annex A.

3.2.1 Introduction

Monitoring of the Total

Suspended Particulates (TSP) levels should be carried out to ensure that

construction works and operation/ restoration of SENTX will not cause adverse

dust impacts to the identified air sensitive receivers. During the aftercare phase, monitoring

of dust should also be conducted when there are major maintenance works. Timely action should be taken to rectify

the situation if an exceedance is detected.

All relevant data including

temperature, pressure, weather conditions, elapsed-time meter reading for the

start and stop of the sampler, identification and weight of the filter paper,

any other special phenomena and work progress of the concerned site should be

recorded. A sample data log sheet

is shown in Annex B.

3.2.2 Monitoring Equipment

A high volume air sampler in

compliance with the following specifications should be used for TSP monitoring:

�P

capable of collecting TSP in the range of 10 to 750 µg m-3;

�P

0.6 to 1.7 m3 min-1 (20-60 SCFM) adjustable

flow range;

�P

equipped with a timing/control device with +/- 5 minutes accuracy

for 24 hours operation;

�P

installed with elapsed-time meter with +/- 2 minutes accuracy for

24 hours operation;

�P

capable of providing a minimum exposed area of 406 cm2

(63 in2);

�P

flow control accuracy: +/- 2.5% deviation over 24-hr sampling

period;

�P

equipped with a shelter to protect the filter and sampler;

�P

incorporated with an electronic mass flow rate controller or other

equivalent devices calibrated against a traceable standard at regular

intervals;

�P

equipped with a flow recorder for continuous monitoring;

�P

provided with a peaked roof inlet;

�P

equipped with a manometer;

�P

able to hold and seal the filter paper to the sampler housing in a

horizontal position;

�P

easy to change the filter; and

�P

capable of operating continuously for 24-hr period.

The Contractor should be responsible

for provision of the monitoring equipment, and should ensure that sufficient

number of high volume air samplers and appropriate calibration kits are

available for carrying out the baseline, impact and ad hoc monitoring. All

the equipment, calibration kit, filter papers, etc. should be clearly labelled.

The Contractor should calibrate

the dust monitoring equipment upon installation and thereafter at bi-monthly

intervals. The transfer standard

should be traceable to the internationally recognised primary standard and be

calibrated annually. The

calibration data should be properly documented for future reference by

concerned parties, such as the IEC.

All the data should be converted into standard temperature and pressure

condition.

The flow-rate of the sampler

before and after the sampling exercise with the filter in position should be

verified to be constant and recorded in the data sheet as described in Section 3.2.1.

Meteorological data should be

obtained from the on-site meteorological monitoring station as described in Section 3.9.

3.2.3 Laboratory

Measurement/ Analysis

A clean laboratory with constant temperature and humidity

control and equipped with necessary measuring and conditioning instruments

should be used for sample analysis and equipment calibration and

maintenance. The laboratory should

be HOKLAS accredited.

If a site laboratory (HOKLAS accredited) is set up or a

non-HOKLAS accredited laboratory is hired for carrying out the laboratory

analysis, the laboratory equipment should be fully justified by ET Leader,

verified by IEC and approved by EPD (EIAO Authority). Measurement performed by the laboratory

should be demonstrated to the satisfaction of the EPD (EIAO Authority) and the

IEC. The IEC should conduct regular

audits of the measurements performed by the laboratory to ensure the accuracy

of the results. The ET should

provide Contractor and the IEC with one copy each of the Title 40 of the Code of Federal Regulations, Chapter 1 (Part 50),

Appendix B and Appendix J for

reference.

Filter paper of size 8"x10" should be labelled

before sampling. It should be a

clean filter paper with no pin hole and should be conditioned in a humidity

controlled chamber for over 24-hr and be pre-weighed before use for the

sampling.

After sampling, the filter paper loaded with dust should be

kept in a clean and tightly sealed plastic bag. The filter paper should then be returned

to the laboratory for reconditioning in the humidity controlled chamber followed

by accurate weighing by an electronic balance with a readout down to 0.1

mg. The balance should be regularly

calibrated against a traceable standard.

All the collected samples should be kept in a good

condition for 6 months before disposal.

3.2.4 Monitoring

Locations

Construction Phase

High volume air samplers (HVSs) should be installed at the

two designated locations at ASRs (i.e. DM1 and DM2) as shown in Figure 3.2a.

DM1 is located at TKO Fill Bank site boundary which is

representative of the impact to the ASRs at the TKO industrial area including

the nearest ASR TVB City.

DM2 is located at the existing TKO Fill Bank site office as

TKO Fill Bank will continue to operate for the next 5 year during the

construction phase of the SENTX; while the two planned ASRs which are the

Construction & Demolition Material Handling Facility and the TKO

Desalination Plant will not exist during construction phase of SENTX by 2021

according to the latest information available.

Operation/Restoration Phase

HVSs should be installed at the four designated locations

along the site boundary (i.e. AM1, AM2, AM3 and AM4) as shown in Figure 3.2a.

Should change of location is required after issuing this EM&A

Manual, the proposed alternative monitoring locations should be fully justified

by ET Leader, verified by IEC and approved by EPD (EIAO Authority).

When alternative monitoring locations are proposed, the

following criteria, as far as practicable, should be followed:

�P

at

the site boundary or such locations close to the major dust emission source(s);

�P

close

to the ASRs; and

�P

taking

into account the prevailing meteorological conditions.

The ET Leader should agree with the Contractor on the position

of the HVSs for installation of the monitoring equipment. When positioning the samplers, the

following points should be noted:

�P

a

horizontal platform should be provided with appropriate support to secure the

samplers against gusty wind;

�P

the

distance between the sampler and an obstacle, such as buildings, should be at

least twice the height that the obstacle protrudes above the sampler;

�P

a

minimum of 2m separation from any supporting structure, measured horizontally

is required;

�P

no

furnaces or incineration flues or building vents are nearby;

�P

airflow

around the sampler is unrestricted;

�P

the

sampler is more than 20m from the drip line;

�P

any

wire fence and gate, to protect the sampler, should not cause any obstruction

during monitoring;

�P

permission

must be obtained to set up the samplers and to obtain access to the monitoring

stations; and

�P

a

secured supply of electricity is needed to operate the samplers.

3.2.5 Baseline

Monitoring

Construction Phase

24-hour TSP levels should be monitored at the two

designated locations (i.e. DM1 and DM2), where there are two existing TSP

monitoring stations operating by the Civil Engineering and Development

Department (CEDD). The recent 1

year historical data at a 6-day interval monitored by the two existing CEDD��s

monitoring stations prior to the commissioning of the construction works will

be used to establish the baseline levels for construction phase. It is more representative to use the

recent 1 year historical data, taking into account of the seasonal variation,

to establish the baseline levels.

Operation/ Restoration &

Aftercare Phases

24-hour TSP levels should be monitored at the four

designated locations along the site boundary (i.e. AM1, AM2, AM3 and AM4) for

at least 14 consecutive days prior to the commissioning of the operation phase

to establish the baseline levels for operation phase. Prior to the commencement of the

operation phase, earthworks and laying of liner should have been completed and

the condition would be representative of the baseline condition prior to the

operation phase. Prior to the

commencement of the construction phase, AM3 and AM4 are located within the TKO

Fill Bank area and the baseline monitoring results would be affected by the

dusty activities in TKO Fill Bank which will not represent the baseline

condition prior to the operation phase of the SENTX. In addition, in terms of technical

feasibility, it is not practical to set up the HVSs at the four monitoring

locations since there is no suitable horizontal platform or secured supply of

electricity prior to the construction phase. Before commencing the baseline

monitoring, the ET leader should inform the IEC and EIAO Authority of the

monitoring programme such that the IEC can conduct on-site audit of the

monitoring.

In exceptional case, when insufficient baseline monitoring

data or questionable results are obtained, the ET Leader should liaise with IEC

to agree on an appropriate set of data to be used as a baseline reference and

submit to EPD (EIAO Authority) for approval.

Ambient conditions may vary seasonally and should be

reviewed at quarterly intervals. If

the ET Leader considers that the ambient conditions have been changed and

repeat of the baseline monitoring is required to be carried out for obtaining

the updated baseline levels, the monitoring should be conducted at times when

the Contractor��s activities are not generating dust, at least in the proximity

of the monitoring stations. Should

changes in ambient conditions be determined, the baseline levels and, in turn,

the air quality criteria, should be revised. The revised baseline levels and air

quality criteria should be fully justified by ET Leader, verified by IEC and

approved by EPD (EIAO Authority).

3.2.6 Impact

Monitoring

Impact monitoring should be undertaken during the

construction and operation/restoration of the SENTX, and during aftercare phase

if there are major maintenance works.

Construction Phase

24-hour TSP levels should be measured at the two designated

locations (i.e. DM1 and DM2) at least once every six days during the

construction phase to monitor the dust impacts of construction works.

Operation/ Restoration &

Aftercare Phases

During operation/restoration phase and aftercare period

when there are major maintenance works, 24-hour TSP levels should be monitored

at least once every six days at four designated locations along the site

boundary (i.e. AM1, AM2, AM3 and AM4).

The specific time to start and stop the 24 hours monitoring

should be clearly defined for each location and be strictly followed by the

operator.

The parameters, locations and frequency of dust monitoring

are summarized in Table 3.2a.

Table 3.2a Parameters,

Locations and Frequency of Dust Monitoring

|

Phase

|

Location

|

Frequency

|

Parameter

|

|

Baseline monitoring

|

At two designated locations (i.e. DM1 and

DM2)

|

Once every 6 days of the recent 1 year

|

�P 24-hr

TSP

|

|

|

At four designated locations along the SENTX

site boundary (i.e. AM1, AM2, AM3 and AM4)

|

At least 14 consecutive days prior to the commencement

of the operation phase

|

�P 24-hr

TSP

|

|

Construction

|

At two designated locations (i.e. DM1 and

DM2)

|

Once every 6 days

|

�P 24-hr

TSP

|

|

Operation/ Restoration

|

At four designated locations along the SENTX

site boundary (i.e. AM1, AM2, AM3 and AM4)

|

Once every 6 days

|

�P 24-hr

TSP

|

|

Aftercare

|

At four designated locations along the SENTX

site boundary (i.e. AM1, AM2, AM3 and AM4)

|

Once every 6 days when there are major

maintenance works

|

�P 24-hr

TSP

|

3.2.7 Event

and Action Limits for Dust

The baseline dust monitoring results and

the Air Quality Objectives (AQOs) form the basis for determining the dust

criteria for impact monitoring. The

ET should compare the impact monitoring results with dust criteria. In case of non-compliance with the dust

criteria, more frequent monitoring, as specified in the EAP (see Section 3.6), should be conducted. This additional monitoring should be

continued until the non-compliance is rectified. Actions in accordance with the EAP (see Section 3.7) should be carried out in

case non-compliance occurred.

Table

3.2b Action

and Limit Levels for Dust

|

Parameter

|

Action Level

|

Limit Level

|

|

Construction

Phase

|

|

|

|

�P

24-hr TSP Level

|

For baseline level ≤ 200 µg

m-³, Action level = (Baseline level *1.3 + Limit level)/2

For baseline level

> 200 µg m-³, Action level = Limit level

|

260

µg m-³

|

|

Operation/Restoration

Phase

|

|

|

|

�P

24-hr TSP Level

|

Action

level = Limit level

|

260

µg m-³

|

|

Aftercare

Phase when there are major maintenance work

|

|

|

|

�P

24-hr TSP Level

|

Action

level = Limit level

|

260

µg m-³

|

3.3.1 Introduction

The general requirements,

methodology, equipment, and mitigation measures for the monitoring and audit of

ambient methane, VOCs, ammonia and H2S associated with the

operation, restoration and aftercare phases of the Project are described

below. The sampling and analysis

method should be prepared by the ET, in consultation with the IEC.

3.3.2 Sampling Equipment

The Contractor should be responsible for

providing and maintaining a sufficient number of the following instruments for

taking ambient air samples of VOCs, ammonia and H2S.

Methane

The instruments should be able to capture

ambient air into inert sample containers (e.g. low flow-rate pump and tedlar

bags) for direct analysis using gas chromatography. If low flow-rate pump is used, it should

be capable of maintaining a steady flow of air to collect the sample volume

specified, and a rotameter of suitable range to measure flow rate during the

sampling process.

VOCs

Samples for VOCs analysis should

be collected using adsorption tubes containing a solid tenax/charcoal trapping

medium or

pressurised canisters fixed with a flow controller, which should

be able to capture the suite of VOCs as shown in Table 3.3b for laboratory analysis.

Ammonia

The sampling instruments (e.g. low

flow-rate pump and silica gel sampling tubes) should be able to collect samples

for the laboratory analysis for measuring ammonia concentrations in between the

range of 0.02 to 2 mg m-3.

H2S

Cadmium hydroxide solution was used

as the absorbing solution to collect H2S in air with mid-get

impringer. The air sampling flow

rate was set at 1.5 L/min.

3.3.3 Laboratory Measurement/Analysis

Air samples collected for

laboratory analysis of should be transported to HOKLAS registered laboratories

within 24 hours and

analysed within 48 hours.

The following analytical methods should be used:

�P Methane �V gas chromatography with thermal

conductivity detection or non dispersion infrared spectroscopy or equivalent

method approved by the IEC;

�P VOCs �V gas chromatography with mass

selective detection or mass spectrophotometry or equivalent method approved by

the IEC;

�P Ammonia �V NIOSH method S347 or equivalent

method approved by the IEC; and

�P H2S �VUS NIOSH

P&CAM Method 126 or equivalent method approved by the IEC.

The required detection limits for

the methane, VOCs, ammonia and H2S are detailed in Table 3.3a.

Table 3.3a Analytical

Detection Limits for VOCs and Ammonia (a)

|

Analytical Parameters (b)

|

Detection Limit (c)

|

|

Ammonia

|

0.02 mg m-3

|

|

Methane

|

0.0025%

|

|

Methanethiol

|

27 ppb

|

|

Ethanethiol

|

1,400 ppb

|

|

Butanethiol

|

1,400 ppb

|

|

Trichloroethylene

|

0.6 ppb

|

|

Vinyl Chloride

|

2.0 ppb

|

|

Benzene

|

2.0 ppb

|

|

Methylene Chloride

|

1.0 ppb

|

|

Chloroform

|

0.8 ppb

|

|

1,2-dichloroethane

|

0.2 ppb

|

|

Carbon tetrachloride

|

0.2 ppb

|

|

Tetrachloroethylene

|

0.2 ppb

|

|

1,1,1-

trichloroethane

|

0.5 ppb

|

|

1,2-dibromoethane

|

0.5 ppb

|

|

All other VOCs

|

0.25 µg m-3

|

|

H2S

|

1 ppb

|

|

Notes:

(a) Reference to the detection limit adopted in the existing

SENT Landfill.

(b) Please refer to the footnote (b) of Table 3.3b

for a full list of 40 VOCs to be monitored.

(c) For parameters not specified in this table, the

detection limit should be 0.25 µg m-3 or better with the exception

of methane which shall be 0.0025% or better.

|

3.3.4 Monitoring Parameter, Location and Frequency

Quarterly monitoring for a period

of 12 months prior to waste filling should be conducted to establish the

baseline ambient methane, VOCs, ammonia and H2S concentrations prior

to landfilling operation. Impact

monitoring should be undertaken throughout the operation/restoration and

aftercare phases of the SENTX and should not be conducted on rainy day. The monitoring frequency, locations, and

parameters are

summarised in Table 3.3b.

Table 3.3b Monitoring

Parameters, Locations and Frequency of Ambient VOCs, Ammonia and H2S

Monitoring

|

Phase

|

Monitoring Locations

|

Monitoring Frequency

|

Parameters

|

|

Baseline

Monitoring

|

4

locations along the SENTX Site Boundary (a)

|

Quarterly,

for a period of 12 months prior to waste filling

|

�P

Methane

�P

Ammonia

�P

A suite of VOCs (b)

�P

H2S

|

|

Operation/

Restoration/Aftercare

|

4

locations along the SENTX Site Boundary (a)

|

Quarterly,

throughout operation/restoration and aftercare phases

|

�P

Methane

�P

Ammonia

�P

A suite of VOCs (b)

�P

H2S

|

|

Notes:

(a)

See Figure 3.2a for the proposed locations.

(b)

A suite of VOCs

includes:

|

|

�P

Trichloroethylene

�P

Vinyl chloride

�P

Methylene chloride

�P

Chloroform

�P

1,2-dichloroethane

�P

1,1,1-trichloroethane

�P

Carbon tetrachloride

�P

Tetrachloroethylene

�P

1,2-dibromoethane

�P

Benzene

�P

Toluene

�P

Carbon disulphide

�P

Propyl benzene

�P

Ethyl benzene

|

�P

Butyl benzene

�P

Xylenes

�P

Decanes

�P

Undecane

�P

Limonene

�P

Terpenes

�P

Ethanol

�P

Butan-2-ol

�P

Dimethylsulphide

�P

Methyl propionate

�P

Ethyl propionate

�P

Propyl propionate

�P

Butyl acetate

�P

Ethyl butanoate

|

�P

Dichlorobenzene

�P

Methyl butanoate

�P

Dipropyl ether

�P

Methanethiol

�P

Ethanethiol

�P

Butanethiol

�P

Methanol

�P

Heptanes

�P

Octanes

�P

Nonanes

�P

Dichlorodifluoro-methane

�P

Methane

|

|

|

|

|

|

3.3.5 Limit Levels for Methane, Ambient VOCs, Ammonia and H2S

Monitoring

Ambient methane, VOCs, ammonia and H2S

monitoring results will be evaluated against the limit levels. The limit levels at the SENTX boundary are

defined as WHO/USEPA/CARB��s ambient criteria if available or the odour

thresholds or 1% of Workplace Exposure Limit (WEL) as stipulated in the ��UK Health and

Safety Executive (HSE) EH 40/2005

Workplace

Exposure Limits��, whichever is lower.

In case of exceedance of the limit levels, more frequent

monitoring, as specified in the EAP (see Section

3.8) should be

conducted. This additional

monitoring should be continued until the non-compliance is rectified.

3.4.1 Introduction

The

performance of the thermal oxidiser should

be monitored when the LTP is in operation.

The purpose of the monitoring is to ensure the thermal oxidizer is

operated under its design condition and emission limits.

3.4.2 Monitoring Parameter, Location and Frequency

Gas samples should be

collected from the stack of the thermal oxidiser for laboratory analysis of the

parameters at a frequency as described in Table 3.4a. In addition, the operating conditions of

the thermal oxidiser should also be monitored continuously.

Table 3.4a Monitoring

Parameters and Frequency of Stack of Thermal Oxidiser

|

Phase

|

Monitoring Frequency

|

Parameters

|

|

Operation/ Restoration

|

�P

Monthly for the first

12 months of operation and thereafter at quarterly intervals

|

Laboratory analysis

for

�P

NO2

�P

CO

�P

SO2

�P

Benzene

�P

Vinyl chloride

In-situ

analysis for

�P

Exhaust

gas velocity

|

|

|

�P

Quarterly

for the 1st year of operation (a)

|

Laboratory analysis

for

�P

Non-methane

organic compounds

|

|

|

�P

During commissioning

and thereafter at quarterly intervals if any ammonia is detected during

commissioning stage

|

Laboratory

analysis for

�P

ammonia

|

|

|

�P

Continuously

|

�P

Gas combustion

temperature

�P

Exhaust temperature

�P

Exhaust gas velocity (b)

|

|

Notes:

(a)

The monitoring results will be reviewed towards the

end of the first year of operation to determine if monitoring of this

parameter can be terminated upon agreement by the EIAO Authority, IEC and

Project Proponent.

(b)

The exhaust gas velocity will be calculated based on

the cross-section area of the stack and continuous monitored gas flow and

combustion temperature data.

|

Under the combustion

temperature of the thermal oxidiser, all ammonia will be destroyed. To confirm this design assumption, it is

recommended that the ammonia concentration in the flue gas of the thermal

oxidiser be monitored during the commissioning stage of the thermal

oxidiser. If required, an emission

standard will be set for ammonia for the thermal oxidiser based on the monitoring

results and to be fully justified by ET Leader, verified by IEC and approved by

EPD (EIAO Authority). If no ammonia is detected in the flue

gas during the decommissioning stage, the monitoring of ammonia in the flue gas

of the thermal oxidiser could be discontinued.

3.4.3 Monitoring Equipment

The Contractor

should be responsible for providing and maintaining a sufficient number of the

following monitoring equipment.

Air Sampling Equipment

The

sampling equipment should

be able to capture emission from the stack into inert sample containers for

direct analysis on a gas chromatography in the laboratory. The

method for the monitoring should be proposed by the ET and agreed with the Project Proponent

in consultation with the IEC.

Gas Combustion Temperature, Exhaust Gas Temperature

A

built-in monitoring system should be installed in the thermal oxidiser, which

should be capable of continuous monitoring of gas combustion temperature and

the exhaust gas temperature.

3.4.4 Laboratory Analysis

Gas

samples should be transferred to the analytical laboratory within 24 hours of

collection and analysed within 48 hours after collection.

Bulk

gas samples should be analysed by gas chromatography for the parameters listed

in Table 3.4a to detection limit of

0.0025% or lower unless other specified.

The carrier gas to be used for the analysis should be helium, hydrogen

or nitrogen with a minimum purity of 99.995%.

3.4.5 Impact Monitoring

The ET should carry out

impact monitoring when the thermal oxidiser is in operation.

3.4.6 Performance Compliance

The

limit levels for NO2, CO, SO2, benzene and vinyl chloride

from the stack emission and gas combustion temperature presented in Table 3.4b should be met. The gas combustion temperature should

also comply with the design parameters of the thermal oxidiser. These parameters have been updated as

per the latest design and the air quality still complies with the prevailing

AQOs. In

case of non-compliance with the limit levels, more frequent monitoring and actions

in accordance with the EAP (see Table

3.8b) should be carried out.

If ammonia is detected during

the commissioning stage, an emission standard will be set for ammonia for the

thermal oxidiser based on the monitoring results and to be fully justified by

ET Leader, verified by IEC and approved by EPD (EIAO Authority).

Table 3.4b Limit Levels for

Stack Emission of the Thermal Oxidiser

|

Parameter

|

Limit Level

|

|

NO2

|

1.58

gs-1

|

|

CO

|

0.53

gs-1

|

|

SO2

|

0.07

gs-1

|

|

Benzene

|

3.01

x 10-2 gs-1

|

|

Vinyl

chloride

|

2.23

x 10-3 gs-1

|

|

Gas

combustion temperature

|

850oC

(minimum)

|

|

Exhaust

gas exit temperature

|

443K

(minimum) (a)

|

|

Exhaust

gas velocity

|

7.5

ms-1 (minimum) (a)

|

|

Note:

(a)

Level under full load condition.

|

3.5.1 Introduction

The performance

of the landfill gas flares should be monitored when they

are in operation. The purpose of

the monitoring is to ensure the flares are operated in compliance with their

design conditions and emissions standards.

3.5.2 Monitoring Parameter and Frequency

The operating conditions

(i.e. gas combustion temperature and exhaust gas velocity) of the flare should

be monitored continuously. Exhaust

gas samples should be collected for laboratory analysis of NO2, CO,

SO2, benzene and vinyl chloride. Table

3.5a summarised the monitoring parameters, locations and frequency of the

emissions from the flares.

Table 3.5a Monitoring

Parameters, Location and Frequency of Stack of the Flares

|

Phase

|

Monitoring Frequency

|

Parameters

|

|

Operation/ Restoration

and aftercare

|

�P

Monthly for the first

12 months of operation and thereafter at quarterly intervals (a)

|

Laboratory

analysis for

�P

NO2

�P

CO

�P

SO2

�P

Benzene

�P

Vinyl chloride

In-situ analysis for

�P

Exhaust

gas velocity

|

|

|

�P

Quarterly for the 1st

year of operation (b)

|

Laboratory

analysis for

�P

Non-methane

organic compounds

|

|

|

�P

Continuously

|

�P

Gas combustion

temperature

�P

Exhaust temperature

�P

Exhaust gas velocity (c)

|

|

Notes:

(a) Reduction

of monitoring frequency will be subject to the monitoring results to

demonstrate environmentally acceptable performance.

(b) The

monitoring results will be reviewed towards the end of the first year of

operation to determine if monitoring of this parameter can be terminated upon

agreement by the EIAO Authority, IEC and Project Proponent.

(c) Exhaust

gas velocity will be calculated based on the cross-section area of the stack

and continuous monitored gas flow and combustion temperature data.

|

3.5.3 Monitoring Equipment and Laboratory Analysis

The monitoring

equipment and laboratory analysis requirements are the same as those for

thermal oxidiser (see Sections 3.4.3 and 3.4.4)

3.5.4 Impact Monitoring

The Contractor should carry

out impact monitoring when the flares are in operation.

3.5.5 Performance Compliance

The

limit levels for NO2, CO, SO2, benzene and vinyl chloride

from the stack emissions and gas combustion temperature presented in Table 3.5b should be met. The gas combustion temperature should

also comply with the design parameters of the flares. These parameters have been updated as

per the latest design and the air quality still comply with the prevailing

AQOs. In

case of non-compliance with the action levels, more frequent monitoring and

actions in accordance with the EAP (see Table

3.8b) should be carried out.

Table 3.5b Limit Levels for

Gas Flare Stack Emission

|

Parameter

|

Limit Level

|

|

NO2

|

0.97 gs-1

|

|

CO

|

2.43 gs-1

|

|

SO2

|

0.22 gs-1

|

|

Benzene

|

4.14 x 10-4 gs-1

|

|

Vinyl Chloride

|

2.60 x 10-4 gs-1

|

|

Gas combustion temperature

|

815oC (minimum)

|

|

Exhaust gas exit temperature

|

923 K (minimum) (a)

|

|

Exhaust gas velocity

|

9.0 m s-1 (minimum) (a)

|

|

Note:

(a)

Level

under full load condition

|

|

3.6.1 Introduction

The performance of the LFG

generator should be monitored. The purpose

of the monitoring is to ensure that the generators are operated in compliance

with their design conditions and emissions standards.

3.6.2 Monitoring Parameter and Frequency

The operating conditions (ie gas

combustion temperature and exhaust gas velocity) of the generator stack should

be monitored continuously. Exhaust

gas samples should be collected for laboratory analysis of NO2, CO,

SO2, benzene and vinyl chloride. Table

3.6a summarised the monitoring parameters, locations and frequency of the

emissions from the generator stack.

Table 3.6a Parameter,

Location and Frequency of Stack of the LFG Generator

|

Phase

|

Monitoring Frequency

|

Parameters

|

|

Operation/

Restoration and aftercare

|

�P

Monthly for the first 12

months of operation and thereafter at quarterly intervals (a)

|

Laboratory

analysis for

�P

NO2

�P

CO

�P

SO2

�P

Benzene

�P

Vinyl chloride

In-situ analysis for

�P

Exhaust

gas velocity

|

|

|

�P

Quarterly

for the 1st year of operation (b)

|

Laboratory

analysis for

�P

Non-methane

organic compounds

|

|

|

�P

Continuously

|

�P

Exhaust temperature

�P

Exhaust gas velocity (c)

|

|

Notes:

(a) Reduction

of monitoring frequency will be subject to the monitoring results to

demonstrate environmentally acceptable performance.

(b) The

monitoring results will be reviewed towards the end of the first year of

operation to determine if monitoring of this parameter can be terminated upon

agreement by the EPD (EIAO Authority), IEC and Project Proponent.

(c) Continuous

monitoring of exhaust gas velocity will be calculated based on the

cross-section area of the stack and continuous monitored gas flow and

combustion temperature data.

|

3.6.3 Monitoring

Equipment and Laboratory Analysis

The monitoring equipment and laboratory analysis requirements

are the same as those for thermal oxidiser (see Sections 3.4.3 and 3.4.4)

3.6.4 Impact

Monitoring

The Contractor should carry out impact monitoring when the

generator is in operation.

3.6.5 Performance

Compliance

The limit levels for NO2, CO, SO2,

benzene and vinyl chloride from the stack emissions as presented in Table 3.6b should be met. The gas combustion temperature should

comply with the design parameters of the generator. These parameters

have been updated as per the latest design and the air quality still complies

with the prevailing AQOs. In case of non-compliance

with the action levels, more frequent monitoring and actions in accordance with

the EAP (see Table 3.8b) should be

carried out.

Table 3.6b Limit Levels for

LFG Generator Stack Emission

|

Parameter

|

Limit Level

|

|

NO2

|

1.91 g s-1

|

|

CO

|

2.48 g s-1

|

|

SO2

|

0.528 g s-1

|

|

Benzene

|

2.47 x 10-4 g s-1

|

|

Vinyl chloride

|

1.88 x 10-5 g s-1

|

|

Gas combustion temperature

|

450oC (minimum)

|

|

|

Exhaust gas exit temperature

|

723K (minimum) (a)

|

|

|

Exhaust gas velocity

|

30.0 ms-1 (minimum) (a)

|

|

|

Note:

(a)

Level under full load condition.

|

|

|

|

|

|

3.7.1 Introduction

The effectiveness of the odour mitigation measures should

be monitored to ensure that the operation of the SENTX will not cause

unacceptable odour impact on the ASRs.

This Section

describes the EM&A requirements with respect to odour control.

3.7.2 Odour

Patrol

Odour patrol should be carried out during the

operation/restoration phase. Odour

patrol should commence once the SENTX starts receiving waste. During aftercare phase, when there are

maintenance works that require excavation of waste, odour patrol should also be

undertaken.

Daily odour patrol should be conducted jointly by the ET

and the IEC who should have a specific sensitivity to a reference odour (i.e.

on reference materials n-butanol with the concentration of 50ppm in nitrogen

(v/v)). The odour intensity

detected should be based on that determined by the IEC. The patrol frequency shall be 3 times

per day and conducted daily during the first month of operation and reduce to

weekly for another three months should odour not being detected in the first

month and no valid odour complaint cases are received. The patrol frequency shall be reviewed

after the 4-month patrol and reduce to monthly interval thereafter subject to

the patrol findings and odour complaint record. Since 6 January 2016, the SENT Landfill

has been receiving construction waste only, which is significantly less odorous

and no substantiated odour complaint against SENT Landfill were received in

2016 and 2017. It is therefore

considered appropriate to relax the monitoring frequency to monthly, which are

made reference to the odour patrol requirement in other waste treatment

facilities, including Sludge Treatment Facility, Organic Waste Treatment

Facility Phase 1 and Integrated Waste Management Facilities Phase 1.

Each proposed change of odour frequency shall be justified

by the ET Leader and verified by the IEC and will be subject to agreement with

Project Proponent and EPD (EIAO Authority).

In addition, an independent party (who should be a trained

personnel/ competent person as described in Section

3.7.3) should be appointed to undertake odour patrol together with the ET

and the qualified panellist from the IEC at monthly interval. During these patrols, the odour

intensity detected should be based on that determined by the independent third

party.

The parameter, location and frequency of odour patrol are

summarised in Table 3.7a.

Table 3.7a Parameter,

Location and Frequency for Odour Patrol

|

Phase

|

Patrol Locations

|

Patrol Frequency (a)

|

Parameters

|

|

Operation/

Restoration

|

Patrol

along the SENTX Site Boundary

|

Period 1 - First month of operation

Daily,

three times a day in the morning, afternoon and evening/night (between 18:00

and 22:00 hrs) conducted by the ET and the IEC

Three

times per week on different days conducted by an independent third party

together with the ET and IEC (b)

Period 2 - Three months following period 1 (c)

Weekly

conducted by the ET and the IEC

Once every two weeks conducted by an independent third

party together with the ET and IEC (b)

Period 3 - Throughout operation following period 2 (c)

Monthly

conducted by the ET and the IEC

Quarterly

conducted by an independent third party together with the ET and IEC (b)

|

Odour

Intensity (see Table 3.7b)

|

|

Aftercare

|

Patrol along the SENTX Site Boundary

|

Weekly or at least once (c)

when

there are maintenance works required excavation of waste

|

Odour Intensity (see Table 3.7b)

|

|

Notes:

(a)

Reduction of

monitoring frequency will be subject to the monitoring results to demonstrate

environmentally acceptable performance.

(b)

Patrol

shall be scheduled so that they are carried out together with the patrols to

be carried out jointly by the ET and the IEC.

(c)

Commencement

of each period will be justified by the ET Leader and verified by

the IEC and will be subject to agreement with the EPD (EIAO Authority) and

Project Proponent.

(d)

At least once during the maintenance work if the

work lasts less than a week.

|

Odour patrol should be carried out along the SENTX Site

boundary. The odour intensities

detected should be categorised as in Table

3.7b.

Table 3.7b Odour

Intensity Level

|

Class

|

Odour Intensity

|

Description

|

|

0

|

Not

Detected

|

No

odour perceived or an odour so weak that it cannot be easily characterised or

described.

|

|

1

|

Slight

|

Identified

odour, slight

|

|

2

|

Moderate

|

Identified

odour, moderate

|

|

3

|

Strong

|

Identified

odour, strong

|

|

4

|

Extreme

|

Severe

odour

|

Odour patrol should be conducted by trained personnel /

competent persons patrolling and sniffing along the SENTX Site boundary to

detect any odour. The trained

personnel / competent persons shall:

�P

Have

their individual odour threshold of n-butanol in nitrogen gas in the range of

20 to 80 ppb/v required by the Europoean Standard Method (EN 13725);

�P

Be

free from any respiratory diseases;

�P

Not

be allowed to smoke, eat, drink (except water) or use chewing gum or sweets 30

minutes before and during the odour patrol; and

�P

Take

great care not to cause any interference with their own perception or that of

others by lack of personal hygiene or the use of perfumes, deodorants, body

lotions or cosmetics.

The trained personnel/competent persons shall use their

noise (olfactory sensors) to sniff odours along the patrol route. The main odour emission sources and the

areas to be affected by the odour nuisance shall be identified.

3.7.3 Odour

Compliance

Odour Complaint

When a complaint is received regarding odour nuisance, a

complaint log (see Annex B) should be completed

within 24 hours and kept with the Contractor. The form should include but not be

limited to the following:

�P Date

and time of the complaint;

�P Name

and contact information of the complainant;

�P Location

of where the odour nuisance occurred;

�P Characteristics

of the odour;

�P Odour

strength;

�P Meteorological

conditions including temperature, wind speed, wind direction relative humidity

at the time of the complaint; and

�P Operation

activities carried out at the SENTX at the time the nuisance occurred.

Action

and Limit Levels for Odour Patrol

Table 3.7c shows the action and limit

levels to be used. When the action

and limit levels are triggered, investigation should be carried out to identify

the cause of exceedance and actions in accordance with the EAP (see Table

3.8b) should be taken.

Table 3.7c Action

and Limit Levels for Odour

|

Parameter

|

Action

Level

|

Limit

Level

|

|

Perceived odour intensity and odour

complaints

|

�P

Odour intensity ≥

Class 2 recorded; or

�P

One documented

complaint received

|

�P

Odour intensity ≥

Class 3 recorded on 2 consecutive patrol (a) (b)

|

|

Notes:

(a)

i.e. either Class

3-strong or Class 4-extreme odour intensity.

(b)

The exceedances of the

odour intensity do not need to be recorded at the same location.

|

3.8.1 Construction

Phase

In case of non-compliance with the dust criteria mentioned in

the above sections, more frequent monitoring, as specified in Table 3.8a should be conducted within 24

hours after the result is obtained.

This additional monitoring should be continued until the dust levels

fall within the compliance level.

3.8.2 Operation/Restoration

and Aftercare Phase

The ET should take the following

actions during

operation/restoration and aftercare phases of the SENTX when action/limit

levels are exceeded:

�P Inform

the IEC, Contractor and Project Proponent of the exceedence and any known circumstances

associated with the exceedance within 24 hours;

�P Investigate

the cause of exceedance; and

�P Implement

the EAP as shown in Table 3.8b.

Table 3.8a Event

and Action Plan for Dust Monitoring During Construction Phase

|

Action

|

|

Event

|

ET

|

IEC

|

Contractor

|

|

|

Action Level

|

|

|

|